Major equipment

SOLIDWORKS 3D CAD

3D solid milling CAM system TOPcam

3D CAD/CAM

In addition to 3-axis machining, TOPcam has enhanced holes and two-axis machining that have been not good at the conventional 3D CAM system, enabling highly accurate and efficient machining.

In one system, it covers two axes, hole drilling to lathes, compound processing, and simultaneous 5-axis processing, and can integrate CAM systems scattered through conventional machine tools and processing methods, not only improving NC programming efficiency but also maximizing machine tool utilization.

Equipped with a machine simulation, you can check the machine operation while creating a tool path, which dramatically improves work efficiency.

[Simultaneous 4/5 axis processing]

Simultaneous 4/5 axis machining that improves machining accuracy and process integration for complex shapes such as impellers and aircraft parts, as well as for shapes without undercuts.

With TOPcam, you can perform advanced machining, such as converte a 3-axis processing tool path to a simultaneous 5 -axis processing, through a simple operation.

Made by Kodama Corporation

Double-column machining center ①

Kitamura BRIDGE CENTER -10G

Table size

X 3000㎜, Y 1370㎜, Z 950mm

Double column type machining center ②

MAZAK FJV60/80

[Capability and capacity]

Table X-axis length: 2,240mm/88.190in

Table Y-axis length: 1,250mm/49.210in

[Main spindle]

Tool Shank: MAS BT-50

Maximum spindle rotation speed: 18,000min-1

Motor for spindle (30 minutes rating): 37kW/50.0HP

[Automatic tool changer]

Number of knives tools: 60

[Movement amount]

X-axis movement amount: 2,000mm/78.74in

Y-axis movement amount: 1,400mm/55.12in

Z-axis movement amount: 660mm/25.98in

・ Realizing shortening of processing time

High output high speed spindle and rapid traverse rate

・ Providing support for large workpieces.

Gate passing workpieces width: 1,500 mm.

・ The high rigidity structure unique to the double-column structure supports high-precision processing and high efficiency processing.

・ It is equipped with a machining attachment function (option) that realizes high productivity by process consolidation.

・ It is equipped with Mazatrol SmoothG as standard, which realizes excellent operability.

Installed in July 2017

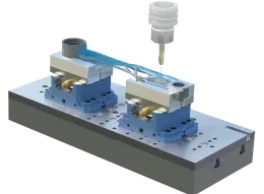

Vertical machining center

OKK VM76R

Table size

X 1540mm

Y 760mm

Z 660mm

Spindle taper №50

With its high rigidity cutting ability,it is effective in processing difficult-to-machine materials such as pre-hardened steel and titanium.

High-precision vertical machining center

OKK VB53

Spindle rotation speed 20,000

Simultaneous 4-axis processing of 1-axis added specifications is possible

Table size

X 1050mm

Y 530mm

Z 510mm

It is effective in manufacturing precision prototype parts.

NC lathe

Yamazaki Mazak 200-Ⅱ MY

φ350×190

Composite lathe with Y-axis milling function

Vertical machining center

Yamazaki Mazak 530C

1050×530×510

Wire-electrical discharge machine

Sodick SL400Q

400×300×250

Three-dimensional measuring instrument

Tokyo Seimitsu RVF1000A-C2

800×1000×600

Image dimension inspection machine

KEYENCE IM-8000

Small-hole electric-discharge machine

Made by Sodick

Horizontal milling machine

Made by Iwashita

Measuring microscope

Mitsutoyo MF-A4020D

400×200

CAD/CAM software

AUTODESK Fusion360